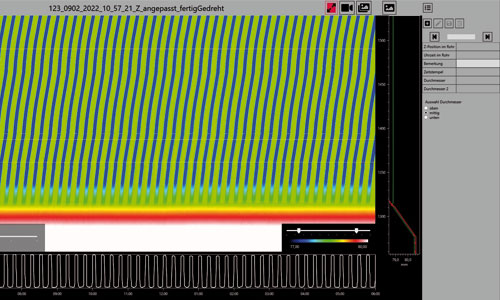

Interactive Software for Reliable Assessment: The extensive data of the inspected surface is analyzed in the user-friendly application software and can be documented and evaluated as a report according to the service regulation TDv018. The interactive interface supports the detection and measurement of critical damaged areas and the final evaluation of the barrel condition and the determination of the remaining service life.

RIB 4D: Inspection System for High-Caliber Gun Barrels

Ensure artillery firing accuracy!

Perfectly maintained tubes for reliable operations and optimum firing accuracy over the entire service life of the system! Use RIB 4D to automatically and reliably detect critical damage spots that could negatively influence the firing accuracy and the safety of the weapon system in field operations.

COTS product: Direct market availability RIB 4D for 120 mm and 155 mm

Other diameter sizes with minor adjustments without new development

Combined laser scan/video scope technology for gun barrel inspection

Superior measuring results, indoor and outdoor!

With the RIB 4D, Kappa presents a new, high-performance system for large-caliber weapon barrel inspection designed for troops evaluating actual and post-firing status and calculating remaining service life.

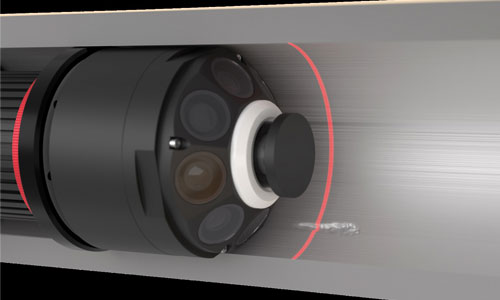

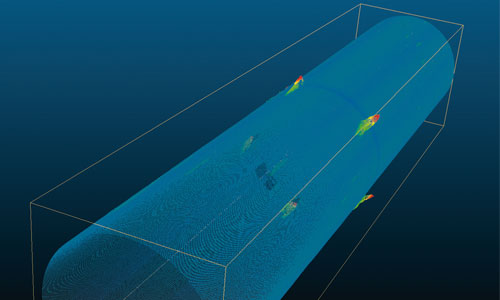

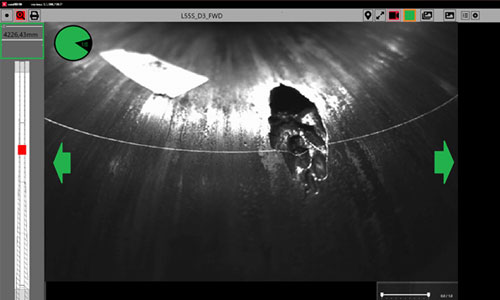

NEW: 3D Laser Scanner and 360° Videos: Within the completely newly designed RIB 4D measuring head, the entire bandwidth of the newest image-generating technology for seamless, complete barrel inspection is used. A supersensitive laser scan generates a detail-rich point cloud. In addition, 8 CMOS sensors provide the viewer with brilliant 360° videos of the barrel’s interior surfaces. The highly precise barrel digitization offers a comprehensive data basis for secure assessment of a barrel interior’s condition.

Keeping it simple: only one operator required

Simple handling means that just one person can operate the entire system. Independent of the operator, the automatic system delivers clear and reproducible measurement results. The barrel digitization is the reliable data basis for the subsequent location-independant assessment of the barrel condition. The compact system is designed for versatile use.

One system for multiple barrel types and diameters

RIB 4D is made for smooth and rifled barrels. With adapter rings, the system can easily be used for different calibers. The current RIB 4D version covers the range from 120 mm to 155 mm. Another version for smaller diameters is in preparation.

Ultra-fast fully-automated barrel digitization (< 30 min.)

The RIB 4D completes the entire high-resolution and precise measurement of the inside of the gun barrel sensationally fast in under 30 minutes (example Leopard 2), which speeds up and largely automates maintenance for system users and thus simplifies it to a great extent.

RIB 4D in Action: Set-up RIB 4D with Leopard 2 and Howitzer 2000

The RIB 4D can be used in different set-ups to measure barrels in assembled and disassembled condition. The barrels can be measured from the muzzle side as well as from the loading side. Bridging a height of up to 2.50 m presents no problems for the drive unit. To measure barrels with different diameters, the adapter rings on the sensor head are simply exchanged (currently available for 120 mm and 150 mm). We show the measurement setup using the Leopard 2 and howitzer 2000 as examples.

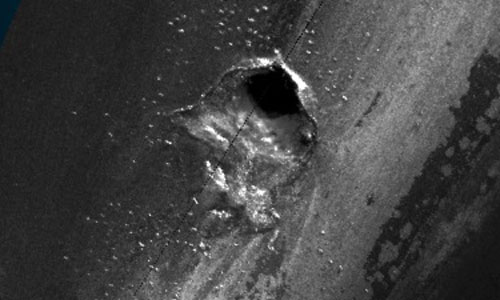

Reliable detection of damage

Precise scanning of the damaged areas - quick location - simple measurement

The system includes the noxRIB4D application software for system control, surface inspection and reporting. In the first step, the pipe is completely digitized on site with RIB 4D. Based on the data, the subsequent analysis can be carried out in the software independent of location. The noxRIB4D software offers two analysis screens, the Heat Map and the Intensity Map, for precise damage analysis. Finally, the analysis results are reported in Excel or TDv018 with evaluation of the barrel condition.

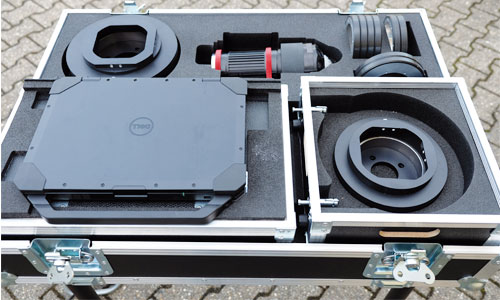

RIB 4D: Overview of the compact system

The RIB 4D is designed for versatile use and easy transport. The system comes in three compact boxes. One box contains the drive unit with the chain, in the second box is the server ( one transport unit with box 1). The third box becomes a control desk for the operator in no time with the included feet. There he controls the measuring process via the included laptop, also a remote control can be used. The measuring head is also stowed here. Also at hand: the adapter rings for 120 mm and 155 mm barrel diameters and the calibration units for calibrating the measuring head.