- Single-person operation

- Pneumatic feed system

- Unique caterpillar-like movement

- Automatic reverse function

- Tool-free assembly and brush replacement

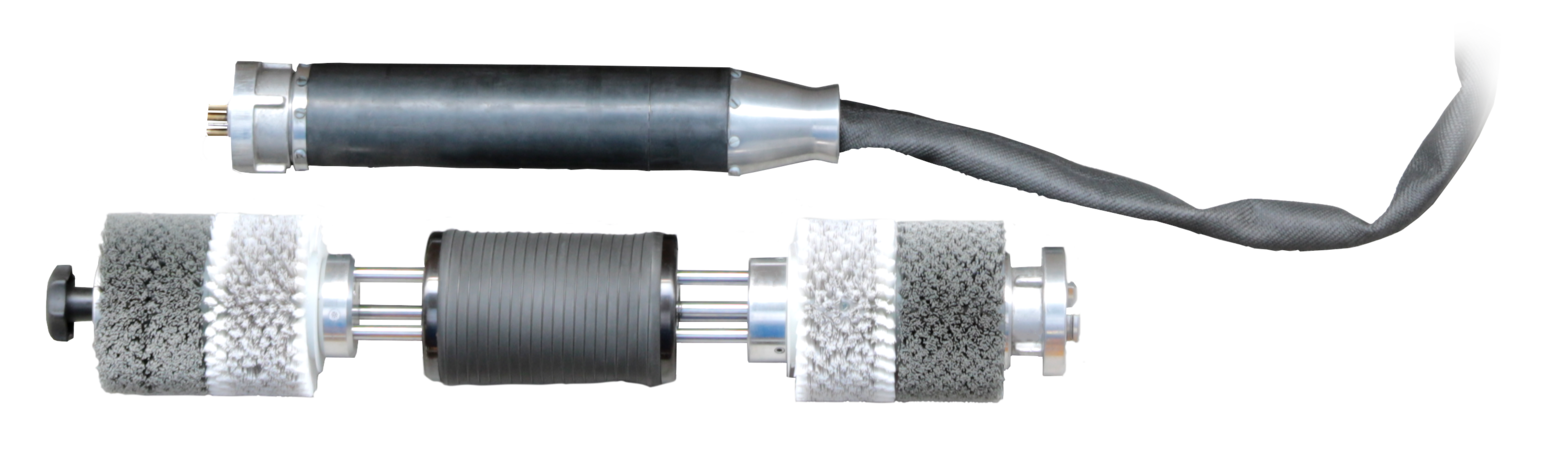

The GunFlash EVO System delivers exceptional cleaning efficiency for gun barrels, making it the perfect complement to Kappa’s RIB 4D inspection systems. Together, they ensure that gun barrels remain in optimal and precise condition for long-term use.

The system, developed by the renowned Niebling Group—specialists in technical and industrial brushes—is exclusively distributed by Kappa.

Automatic, precise & efficient

The system enhances shooting accuracy and prevents corrosion by ensuring that gun barrels are clean and free from contaminants, and regularly inspected for wear. This not only extends the lifespan of the barrels but also significantly reduces the cleaning effort. Consequently, operational performance and safety are improved, ensuring that your guns consistently fire with precision and reliability.

The innovative cleaning system offers numerous advantages. Notably, its ease of use with single-person operation makes it both flexible and practical. The pneumatic feed system ensures consistent and powerful advancement with a unique caterpillar-like movement. The automatic reverse function provides smooth operation, while the tool-free assembly and brush replacement significantly simplify maintenance and handling. Additionally, optional power supply through tanks or trucks is feasible.

SmartView - HD camera system

The camera system enables visual inspection through a high-resolution HD display, allowing the examination and documentation of cleaning results. Technical specifications include a real-time video transmitter, LED lighting, and USB capability. The tool-free installation on the GunFlash and storage in a safety case complete the package.

SmartComp - Compressor

The diesel compressor can operate independently in the field and is also suitable for stationary fixed connections. It operates at a pressure of 8 bar and provides an operating power of 24 volts / 3 amperes. Its autonomous continuous operation ensures high reliability and efficiency. The total weight is 83 kg without the transport box and 87 kg with the transport box.

Evolution Visible Optimized

The GunFlash EVO system features upgraded electronics, improved handling, and a new camera system. The durable brush hose and new oil management ensure longevity and reduced maintenance. Additionally, a custom camouflage pattern for the aluminum transport box and brush hose is available.