Step 01

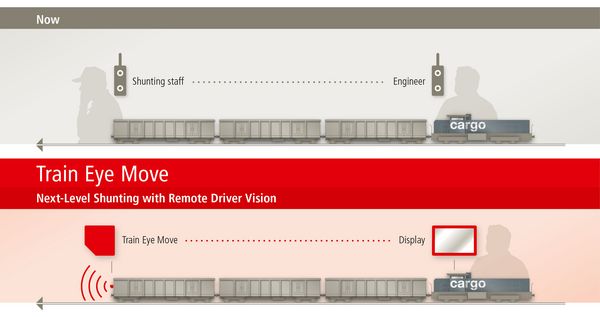

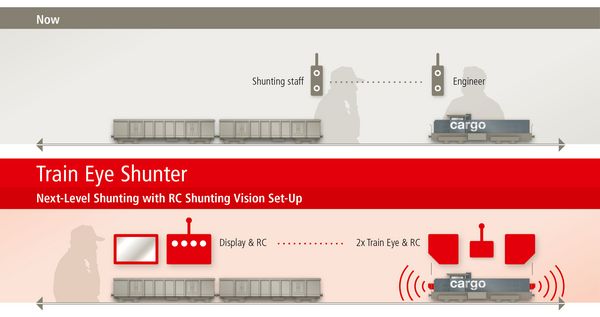

Shunting video assistant Train Eye "Move" and the system Train Eye "Shunter" ensure safe one-person operation. Increase shunting operations with low-threshold investments within structures already in place.

Efficiency Leap: save time, move more tonnage, minimize accident risks, reduce costs: Rail transport is facing a massive challenge in the future to move more tonnage in less time, more economically, and more safely, all while dealing with current staffing shortages. Camera-based solutions provide drastic, rapid support, building upon existing resources, and infrastructure. Our new Train Eye program concept encompasses mobile entry-level solutions to improve safety and efficiency, up to complete driver vision and driver assistance systems.Kappa is your partner for certifiable solutions SIL 2 / SIL 3. Certifiable vision systems for safety-critical applications are our core business. Communication at eye level and in-depth understanding of your specific requirements are the basis for our solutions.

With the entry-level Train Eye Move, staff can visually shunt extremely long blocks safely in one-man operation. Plug & Go: The lightweight video box is mounted magnetically onto the necessary end of the train and transfers sight forward, latency-free, to the shunting staff – totally simple.

With Train Eye Shunter, an existing shunting locomotive fleet can be retrofitted for safe remote operation. 2 video boxes with additional radar/LIDAR sensors are permanently mounted onto the locomotive in front and back. The system is connected to the radio remote control. Shunting staff steer off rail — or even from the office.

Minimized accident risks

Move more tonnage

Save time & costs

Business Unit Manager Vision Solutions

![[English] Harold O'Grady, Kappa optronics Inc., USA Team Account Manager](/fileadmin/_processed_/1/b/csm_kappa-usa-team-harold_1c2b08e6a6.jpg)

![[English] Harold O'Grady, Kappa optronics Inc., USA Team Account Manager](/fileadmin/_processed_/1/b/csm_kappa-usa-team-harold_5da0f10e4f.jpg)